In industries like construction, manufacturing, and agriculture, your equipment is more than a tool—it’s the foundation of your daily operations. When that equipment breaks or wears down, you’re faced with two options: replace it or repair it. Custom welding is often the faster, more cost-effective solution, especially for Columbus businesses that rely on heavy-duty gear to get the job done.

At Payne Brothers Welding & Fabrication, we help extend the life of your equipment through expert custom welding that’s tailored to your specific needs. Here’s how we do it—and why it matters.

Common Equipment Failures Solved by Welding

Heavy use, exposure to the elements, and high-stress loads all take a toll on machinery. Over time, these common issues arise:

- 🔧 Cracked or broken frames on tractors, trailers, and loaders

- ⚙ Worn-out joints or welds on industrial machinery

- 🔩 Damaged brackets, arms, or mounting points

- 🧱 Rust or corrosion eating through structural components

- 🛠 Broken implements or attachments that no longer function properly

Welding can fix these problems quickly, restoring strength and functionality without the need for full replacement.

Benefits of Repair vs. Replacement

Replacing damaged equipment can be expensive, time-consuming, and sometimes unnecessary. Here’s why custom welding repair is often the better option:

✅ Lower Costs – Welding repairs are typically a fraction of the cost of buying new equipment.

✅ Faster Turnaround – Repairs can often be completed same-day or on-site, getting you back to work quickly.

✅ Custom Fit – Repairs can be modified to better meet your current needs, improving performance.

✅ Extended Equipment Life – Reinforcing or rebuilding key areas extends the usability of your machinery.

✅ Environmentally Friendly – Repairing instead of replacing helps reduce waste and unnecessary manufacturing.

How to Identify Weldable Repairs

Not every failure means you need a new machine. Many damaged components can be restored with the right welding approach. Here’s how to spot a weldable issue:

🔍 Visible Cracks or Breaks – Clean splits in metal frames or brackets are often repairable.

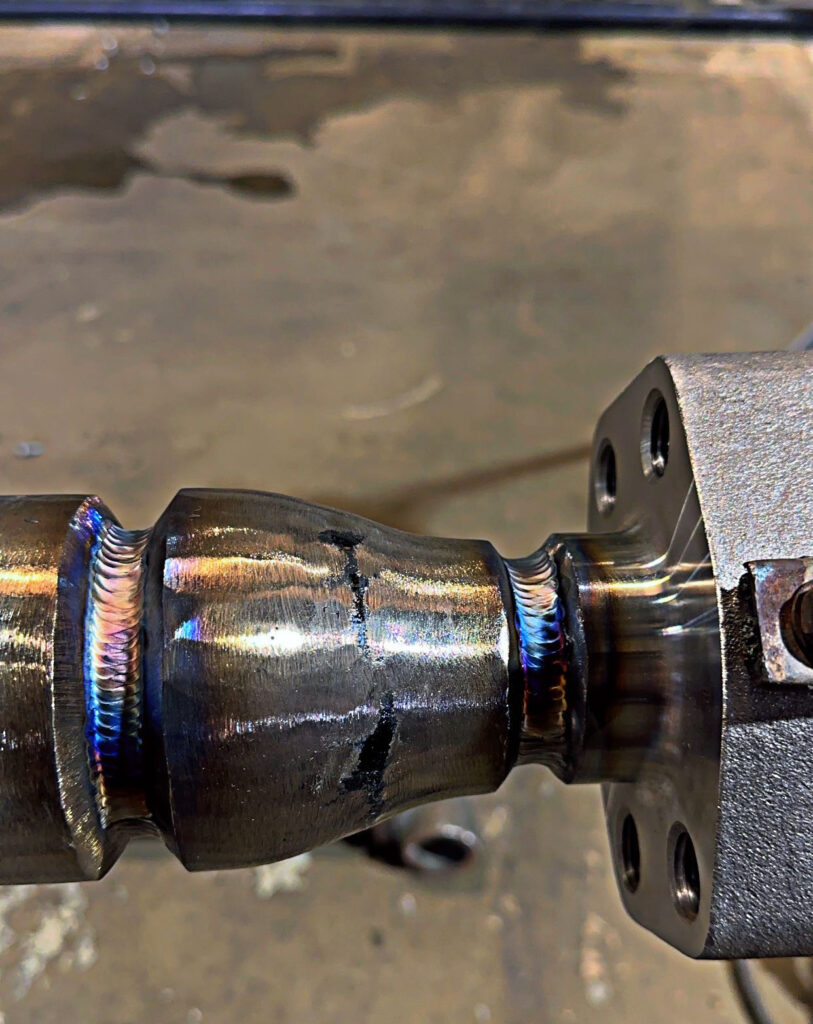

🔍 Fatigue Around Welds – If the original welds are wearing out, they can usually be reinforced or redone.

🔍 Localized Damage – If one part is broken but the rest of the equipment is solid, welding is a smart fix.

🔍 Corrosion in Isolated Areas – Rusted sections can be cut out and patched with fresh metal.

If you’re unsure, our team at Payne Brothers offers free consultations to assess whether your equipment can be saved through welding.

Why Columbus Businesses Trust Payne Brothers

At Payne Brothers Welding & Fabrication, we’re proud to serve Columbus with reliable, custom welding services that extend the life of the tools you rely on.

Here’s what sets us apart:

✔ Mobile Welding – We come to your site for on-the-spot repairs.

✔ Heavy-Duty Expertise – From tractors to production lines, we’ve seen—and fixed—it all.

✔ Fast Turnaround – We know downtime is expensive, so we work quickly without cutting corners.

✔ Precision Craftsmanship – Every weld is done to last, no shortcuts or weak spots.

✔ Local and Trusted – We live and work in the Columbus area, and we’re committed to keeping local businesses moving.

Need a Repair? Let’s Make It Last.

If your equipment is showing signs of wear, don’t wait for a total failure. Call Payne Brothers Welding & Fabrication for custom welding solutions that keep your tools running longer and stronger.

Let’s build something durable—together.